Why I Built It

In December 2022, I came across a video on YouTube in which Alan Zhao, a student at MIT, created his own DIY equatorial mount for astrophotography using a gearing mechanism called a Harmonic Drive. Since I have always been interested in outer space and astronomy, I found the idea of astrophotography quite fascinating.

By January, I decided to design and build my own go-to equatorial mount from the ground up. Using CAD and PCB design skills I developed early on with the Harvard Satellite Team, I started a full mechanical + electrical + software integration project and named it the H.E.I.S.T. Mount (Harvard-Engineered Imaging System and Telescope Mount).

System Goals & Design Choices

The mount was designed to be portable, powerful, and precise.

- Harmonic drives (strain-wave gearing) were chosen to drive a heavy payload with minimal backlash and without counterweights.

- Open-source control compatibility: the electronics were designed to be compatible with OnStep, an open-source telescope control system.

This project was financially supported by the NECTAR Funding program of Harvard SEAS.

High-Level Architecture

At a system level, the mount looks like this:

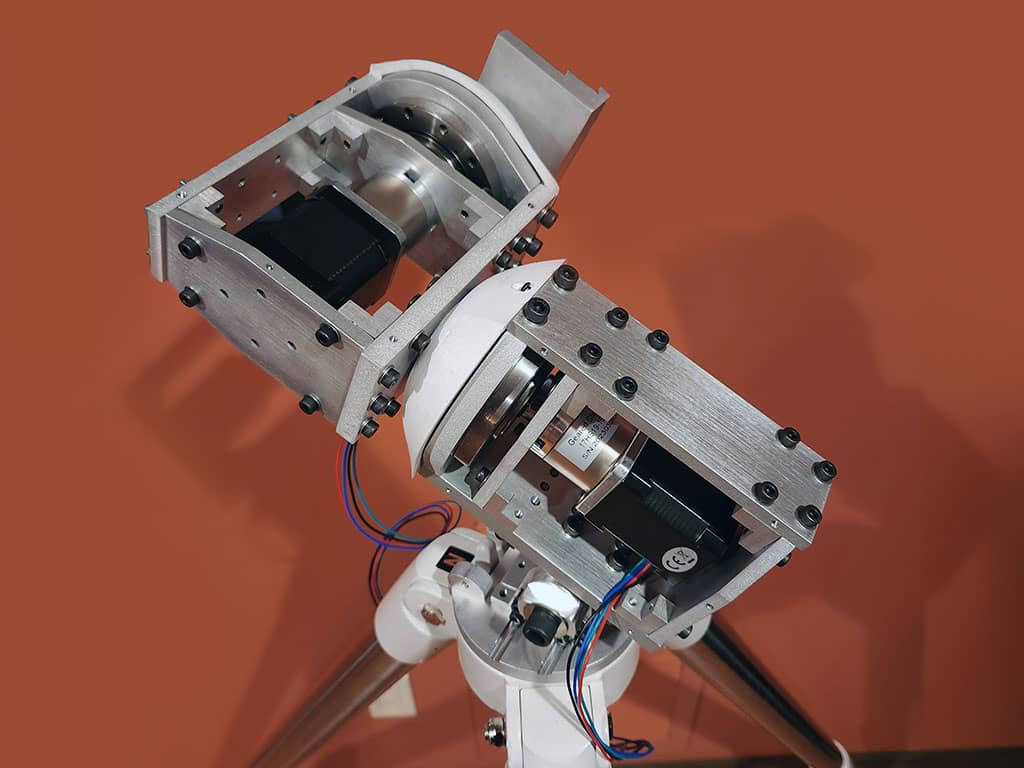

- Mechanical: equatorial mount structure + harmonic-drive gearing + stepper motors

- Electronics: a custom PCB providing power distribution, motor drive, and I/O

- Embedded control: Teensy 4.0 microcontroller running the control firmware stack

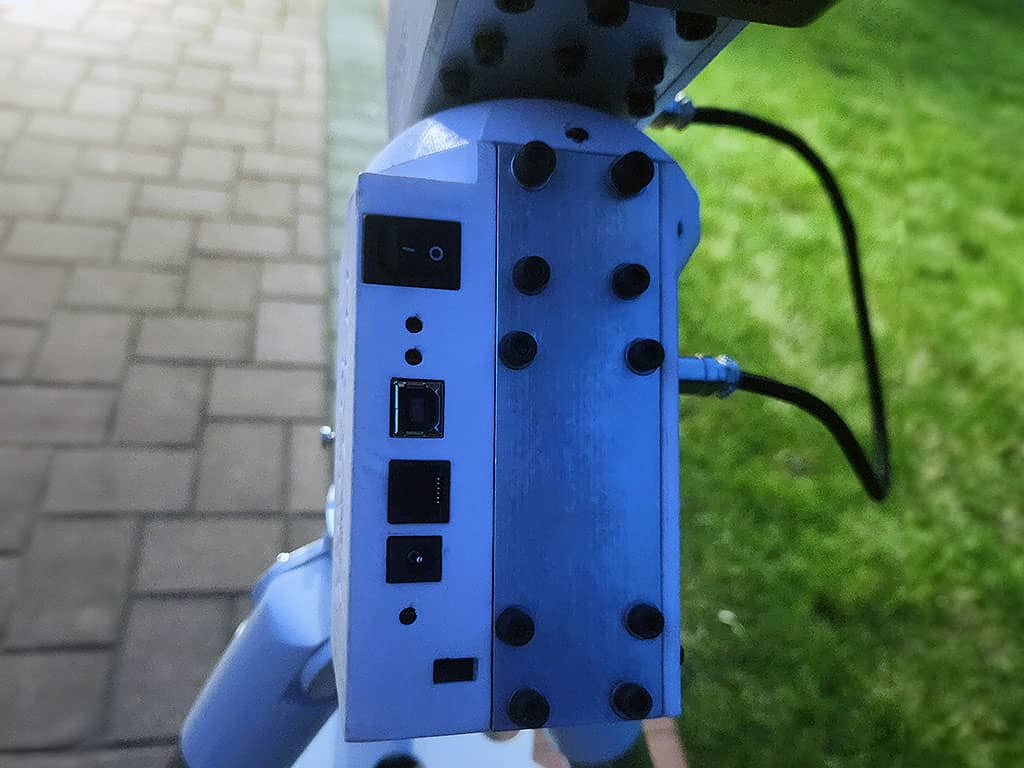

- Interfaces: USB-B for PC connectivity and ST-4 port for autoguiding

Build Process (Mechanical)

To simplify manufacturing while keeping stiffness and durability, most metal parts were designed to be cut from 6061 aluminum on a waterjet. Two components (the dovetail clamp and an altitude lock knob) were manually machined on a mill and a lathe.

This was my first time using a waterjet machine, and it was a great learning experience, especially around process constraints, fixturing, and post-processing. The OMAX software was fairly intuitive, and the machine itself ran very smoothly.

After cutting, the parts required drilling/tapping for side holes, followed by deburring/sanding.

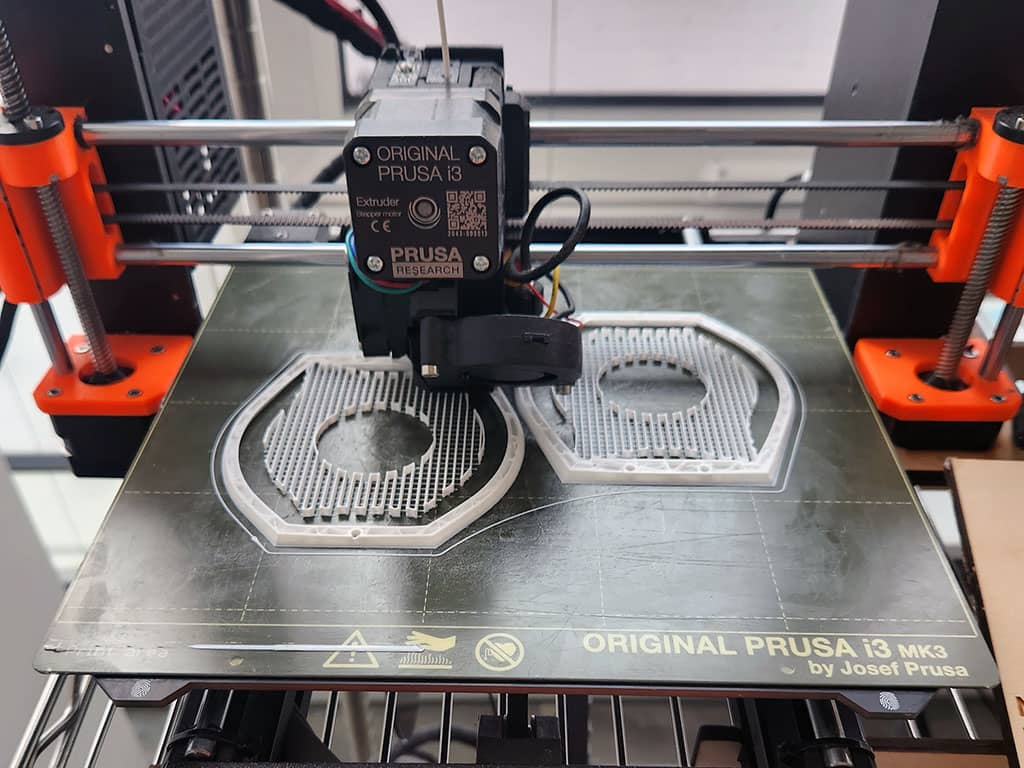

To complete the mechanical system, I 3D-printed the remaining enclosures on a Prusa i3 MK3.

Build Process (Electronics & Embedded Control)

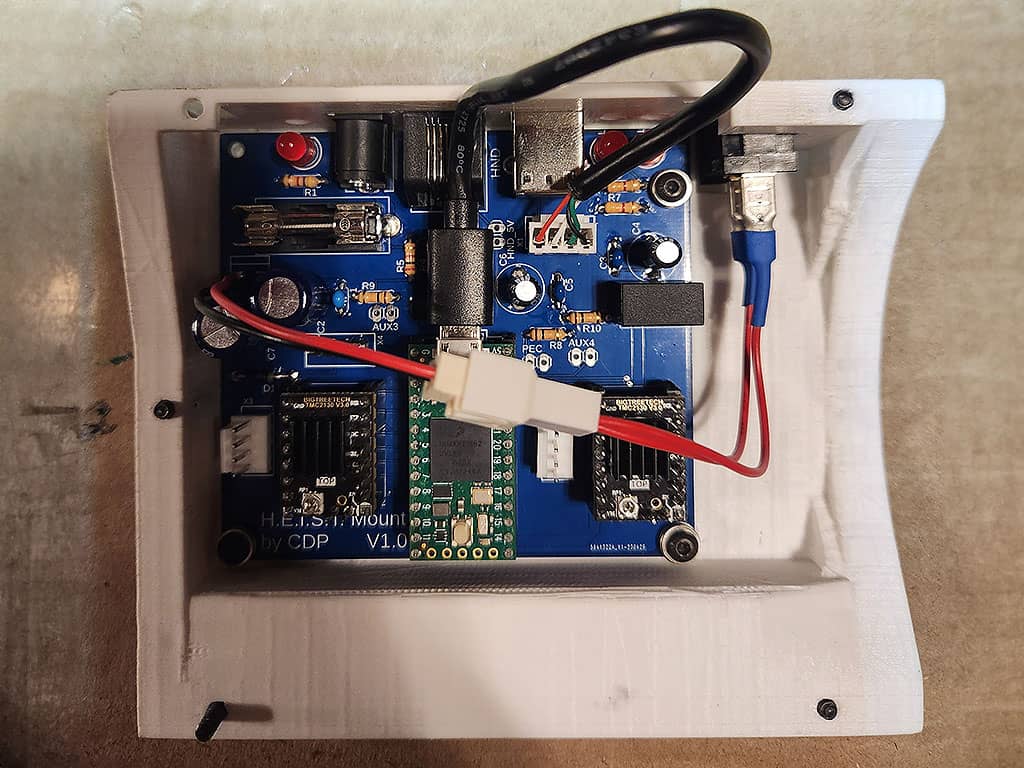

The electronics were built around a custom PCB and a Teensy 4.0 microcontroller.

- Power: 24V input powering the board and motors

- Motor drive: two TMC2130 stepper drivers

- I/O: USB-B for PC control + ST-4 for autoguiding

Here is the PCB after soldering and assembly in the 3D-printed enclosure:

Before final assembly, I decided to test the electronics to validate power distribution, driver configuration, and basic motor control. Nothing caught on fire or exploded, so I considered the test to be a success!

Integration & Results

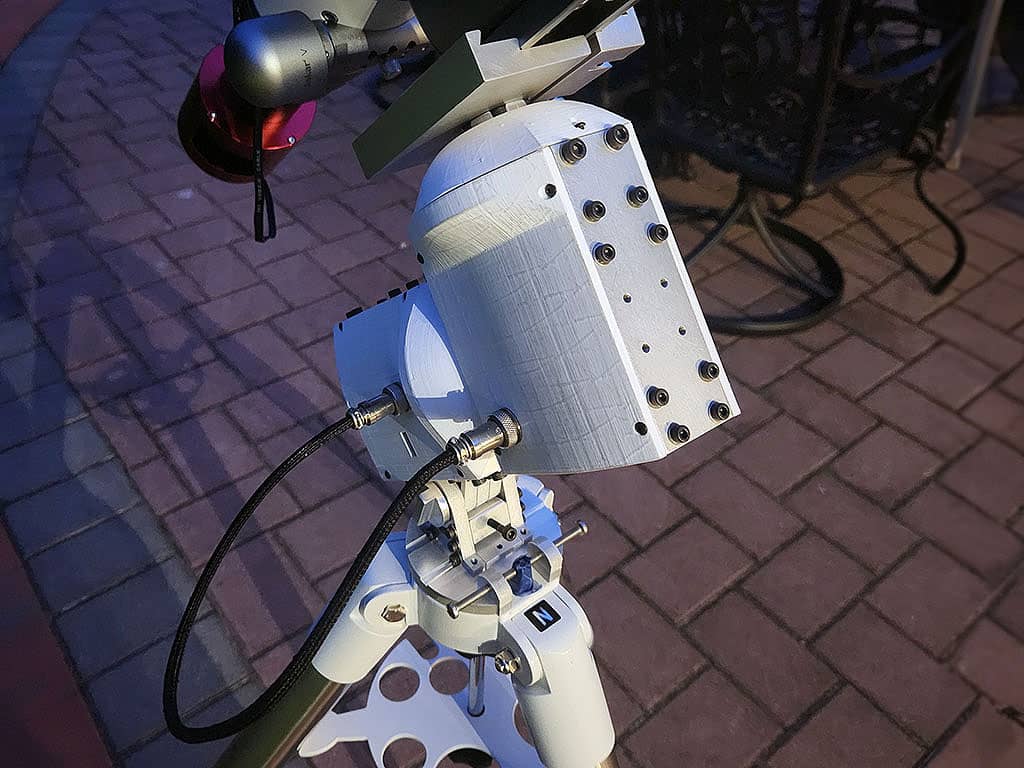

After the subassemblies were complete, I assembled the full mount and began end-to-end testing (mechanics + electronics + control).

Here is a video of the mount in action:

And here is the first image I captured using the H.E.I.S.T. Mount, my Askar V telescope, and a ZWO ASI533MC-Pro camera: a stacked image of Messier 17 (Omega Nebula).

You can check out more astrophotography results in the gallery!