HUCSat is a 2U research satellite deploying from the International Space Station to demonstrate a novel shape-memory-alloy (SMA) solar array orientation mechanism. As Chief Engineer, I led the technical development of this student-built spacecraft from concept through final integration.

Why HUCSat Exists

On small satellites, moving hardware (solar arrays, antennas, sensors, etc.) often means adding motors, geartrains, and control electronics, all of which cost mass, power, and reliability margin. HUCSat explores a lighter-weight alternative: shape-memory alloys (SMAs).

The core idea is very simple:

- Train a nickel–titanium (Nitinol) element to a target shape.

- Electrically heat it (Joule heating) to trigger a phase transition.

- Use the resulting mechanical contraction as an actuator.

HUCSat tests whether an SMA-driven mechanism can provide useful, repeatable motion in the space environment with minimal electronics, which is a result that could inform future low-cost deployments and pointing mechanisms for CubeSats and small satellites.

HUCSat will be deployed from the ISS in 2026 via NASA’s CubeSat Launch Initiative (CSLI) and operated under an amateur radio license.

Mission Goals

HUCSat is designed around a clear set of mission outcomes:

- Safely initialize after ISS deployment, establish communications, and detumble.

- Deploy the payload from its stowed configuration.

- Demonstrate controlled reorientation of the SMA-driven solar panel platform for at least one orbit.

- Downlink telemetry and payload data, including sensor verification of actuation.

Spacecraft Specifications

| Category | Summary |

|---|---|

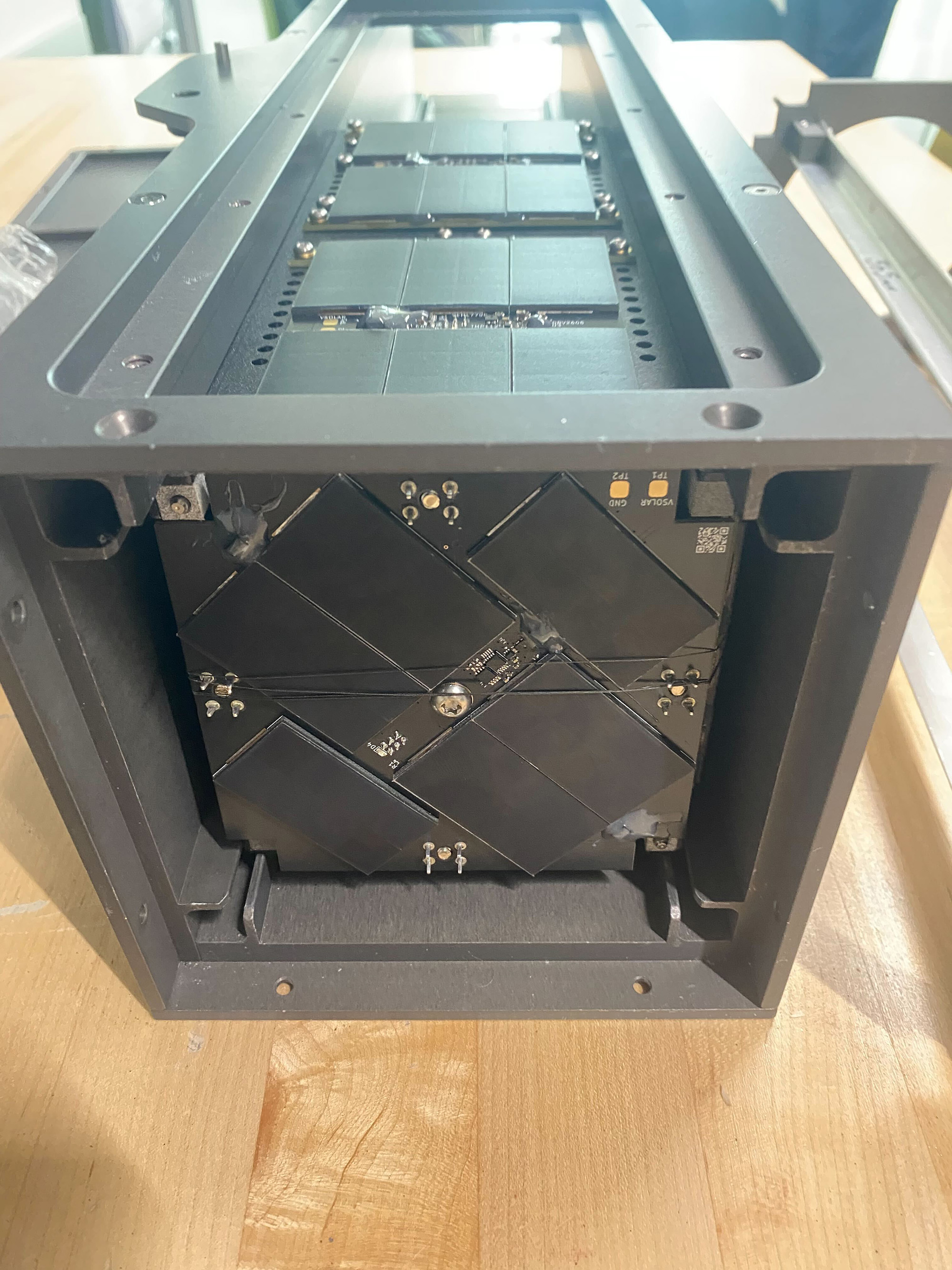

| Form Factor | 2U CubeSat (10 × 10 × 20 cm) |

| Mass | ~2.6 kg |

| Deployment | ISS (NanoRacks CubeSat Deployer) |

| Orbit | ~410 km circular, ~51.6° inclination |

| Communications | UHF LoRa (command/telemetry) + S-band LoRa (payload data) |

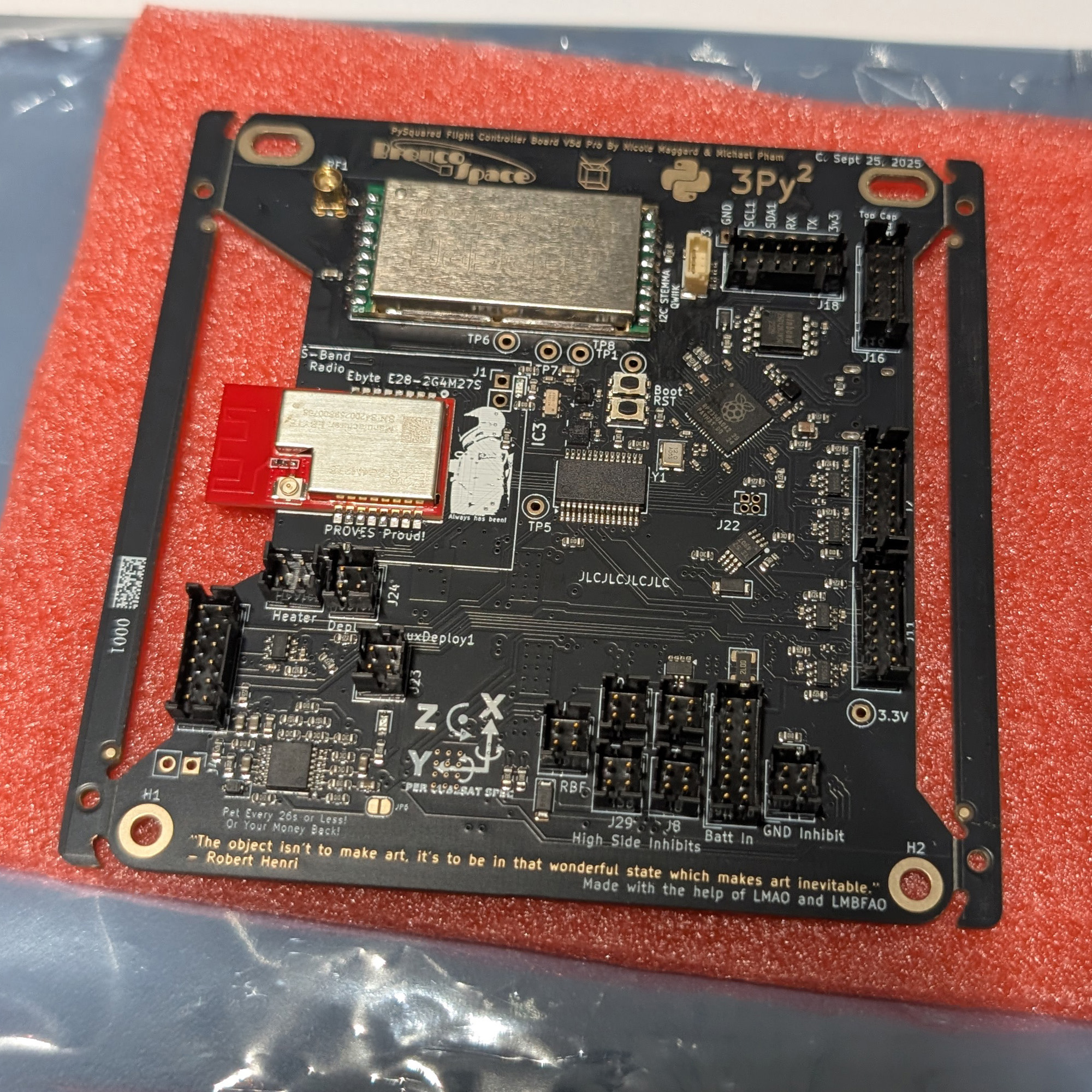

| Avionics | Custom flight controller with watchdog + subsystem interfaces |

| ADCS | IMU + sun sensors + magnetorquers (detumble/coarse control) |

| Power | Body-mounted solar panels + Li-ion battery packs |

| Payload | Deployable solar panel platform with 4 SMA coils |

High-Level Architecture

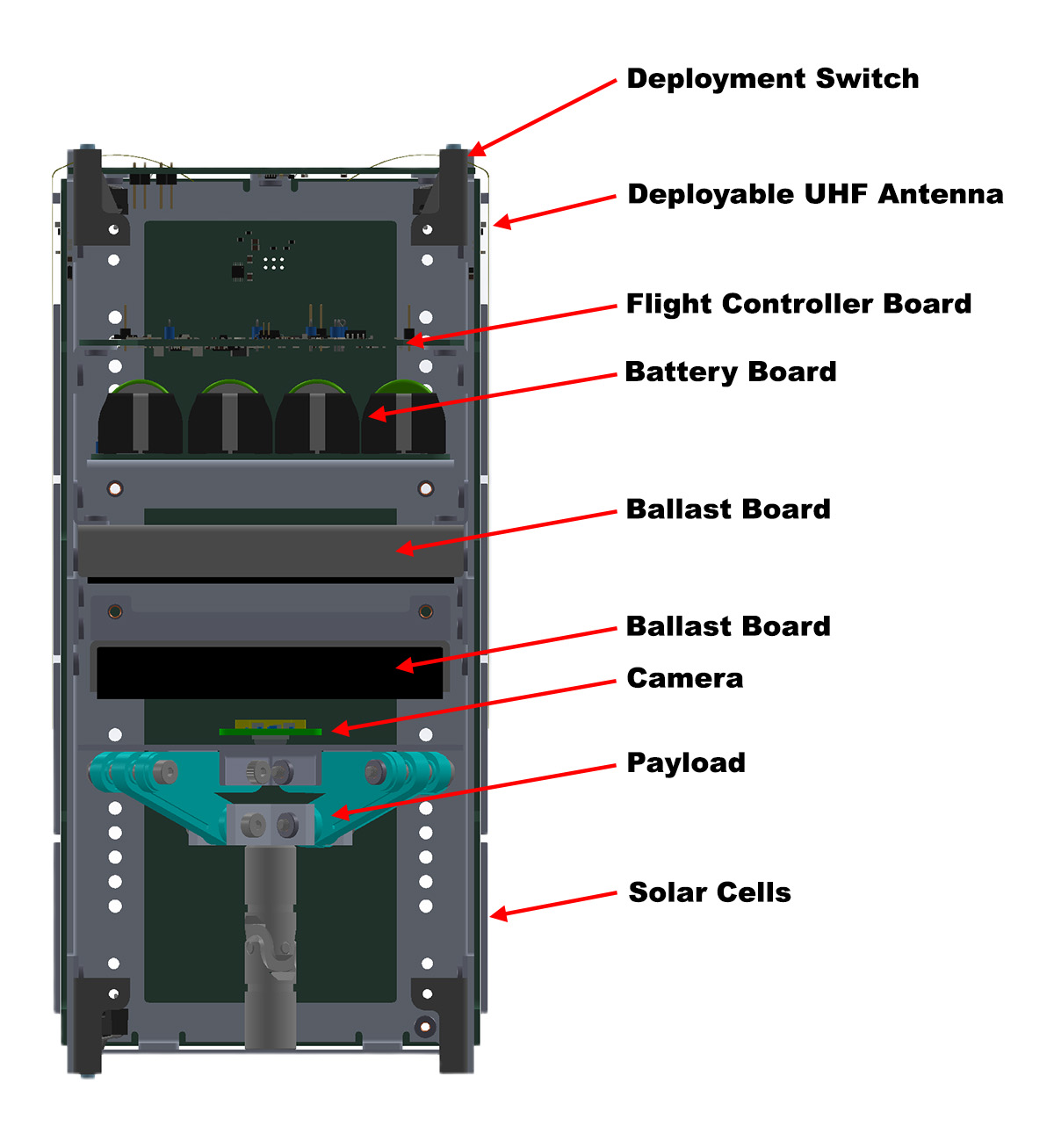

At a system level, HUCSat is a compact, integrated stack: structure, power, avionics, communications, attitude control, and payload.

Subsystem-level architecture showing the deployable antenna, avionics stack, power system, payload volume, and body-mounted solar panels.

Subsystem-level architecture showing the deployable antenna, avionics stack, power system, payload volume, and body-mounted solar panels.

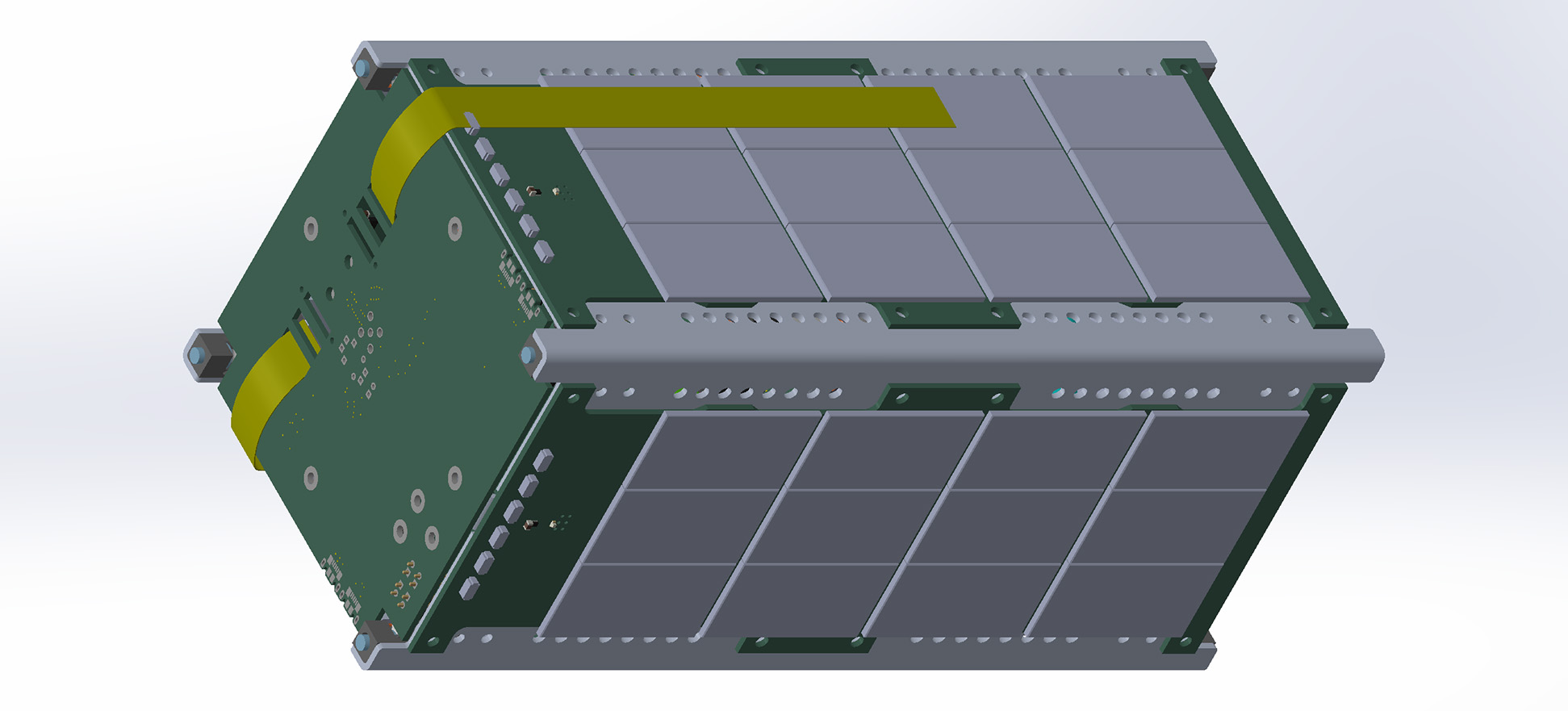

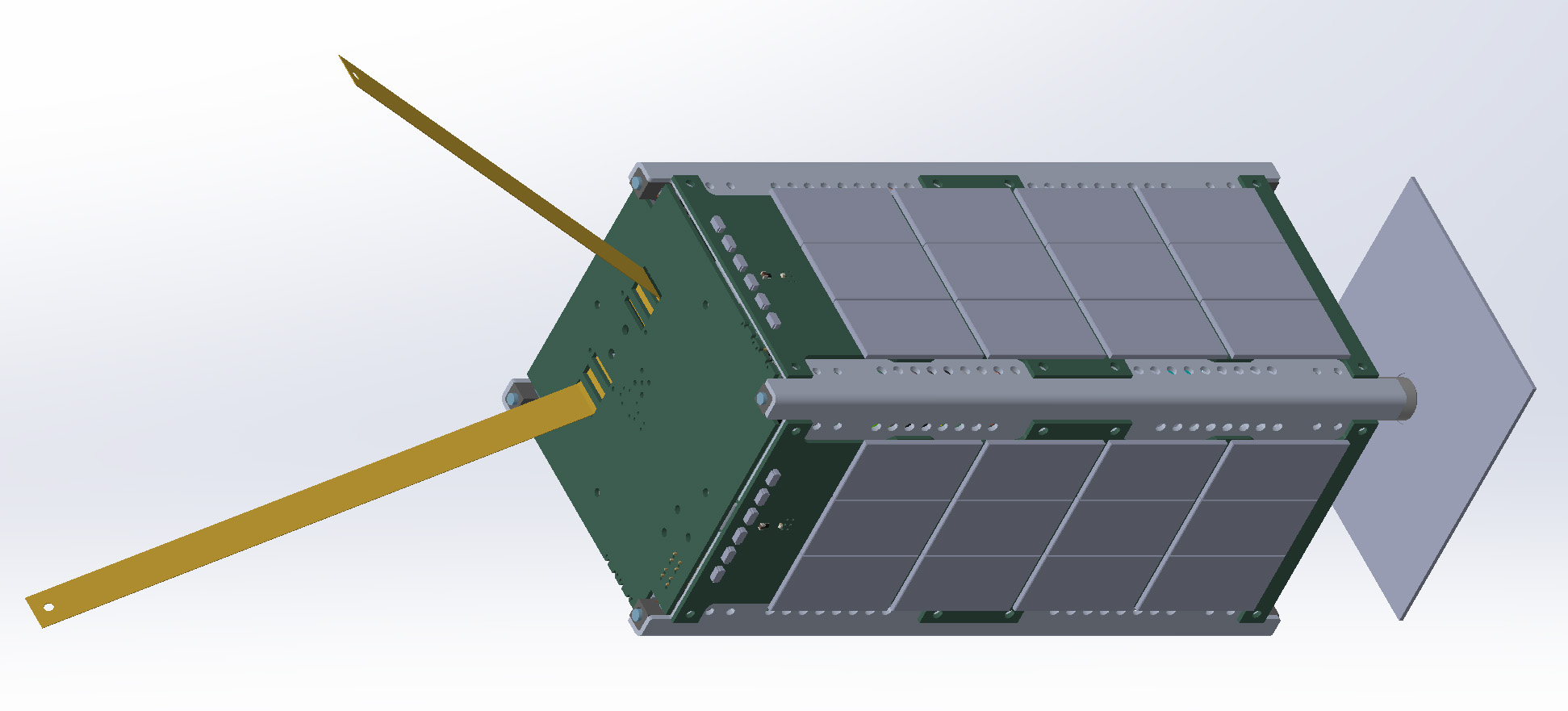

Left: Stowed configuration (as deployed from the ISS). Right: Deployed configuration with antennas and payload platform extended.

The Payload: SMA-Driven Solar Panel Orientation

The payload is a deployable solar panel platform mounted on the spacecraft’s −Z face. After deployment:

- A torsion-spring linkage mechanism lifts the platform away from the body.

- Four Nitinol coils (one per edge) can be selectively heated to generate asymmetric contraction.

- That contraction induces a controlled rotation of the platform to better face the Sun.

The payload is deliberately designed to be:

- Low power — heating only when actuation is needed

- Low part count — no motors or gearboxes

- Software-addressable — selective heating with sensor feedback

- Sensor verifiable — onboard light sensors confirm orientation changes

Subsystems Overview

Structure

HUCSat uses a custom 2U aluminum structure designed around clean board stacking and harness routing, simple manufacturing, and predictable thermal and mechanical behavior during vibration testing and handling.

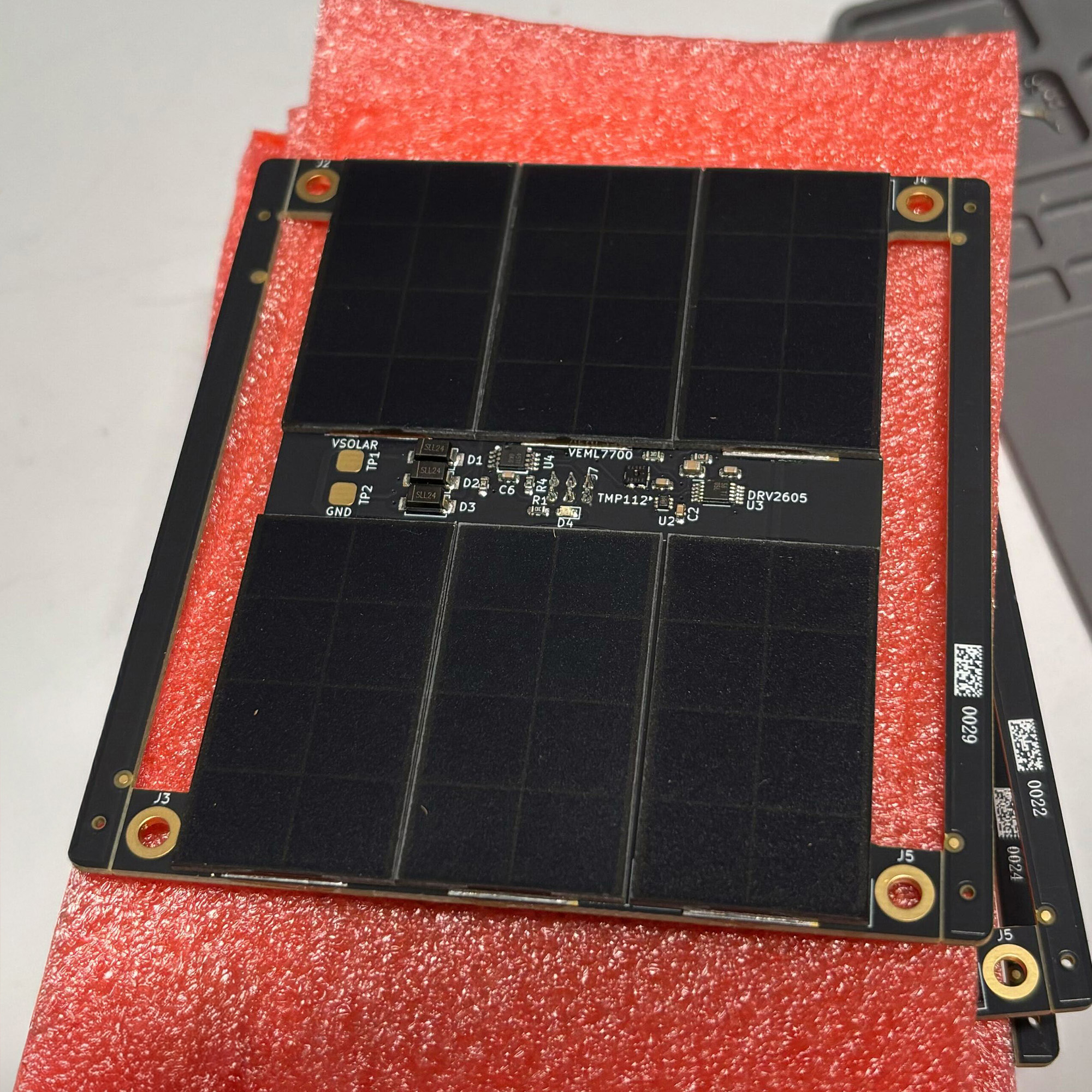

Electrical Power System (EPS)

The EPS supports the ISS deployment mission profile with robust protection:

- Body-mounted solar panels on all XY faces to reduce attitude dependence

- Li-ion energy storage with protection circuitry validated through acceptance testing

- Battery architecture supports safe operations through launch, deploy, and on-orbit cycling

Command & Data Handling (CDH)

The flight computer coordinates boot and deployment timing logic, radio command/telemetry handling, payload scheduling and logging, and fault handling with watchdog-driven recovery.

Attitude Determination & Control (ADCS)

For a 2U satellite, ADCS focuses on reliably reaching a “good enough” attitude:

- 6-axis IMU and sun/light sensors for attitude estimation

- Embedded PCB magnetorquers for detumbling and coarse pointing

Communications & Ground Segment

HUCSat is designed to be operable by Harvard students with modest ground station equipment:

- UHF link for command uplink and telemetry downlink

- S-band downlink for increased payload data throughput

- Telemetry receivable by distributed amateur ground stations (via the TinyGS network)

- All transmissions are command-terminable for positive control

Verification & Testing

HUCSat is being built under a real flight schedule, so verification is structured and evidence-driven. The test program includes component- and subsystem-level verification leading up to acceptance-level environmental testing.

Key verification activities include:

- Battery acceptance testing — over-discharge protection, external short protection, vacuum exposure, and vibration

- Deployment mechanism testing — repeated actuation cycles under thermal vacuum conditions

- End-to-end communications testing — RF link verification with ground station hardware

Licensing & Compliance

A flight mission requires disciplined regulatory and safety work:

- Frequency coordination through IARU for amateur satellite bands

- FCC experimental license application for university spacecraft operations

- Orbital debris assessment documenting passive disposal, collision risk, and reentry safety

- Mission designed for rapid natural decay from ISS orbit with no intentional debris release

My Role

Chief Engineer & Technical Lead

As Chief Engineer, I was responsible for the overall technical direction and delivery of the HUCSat mission, including:

- Systems-level integration planning and interface ownership

- Schedule and milestone tracking with external partners

- Ensuring design choices are testable and verifiable

- Leading design reviews and technical decision-making

Hardware Design (CAD & PCBs)

I led key flight-hardware design work, including:

- Spacecraft CAD model and packaging layout in SolidWorks

- Custom PCB assemblies for the payload’s SMA actuation electronics

- Design-for-assembly practices suitable for student manufacturing pipelines

Team Technical Leadership

I invested in scaling technical capability across the team:

- Ran KiCad PCB design workshops so more students could contribute flight-quality hardware

- Ran SolidWorks design-for-production workshops to standardize mechanical practices

- Supported thermal and orbital analysis workflows to strengthen design closure

Licensing & Documentation

I managed major parts of the small-satellite licensing flow and associated technical documentation, coordinating with licensing consultants and university stakeholders to complete the application package.

Current Status

HUCSat has been delivered to our launch integrator and is scheduled for deployment from the ISS in mid-2026. The team continues to monitor pre-launch status and prepare ground station operations for mission success.

Acknowledgements

HUCSat is the product of sustained work by a large student team over multiple years. I’m grateful to the Harvard Satellite Team for deep technical effort across disciplines, faculty mentorship and support, our launch integration partners, and the amateur satellite community that supports educational missions through shared infrastructure and ground station networks.